صنعتي گريڊ ڪيميڪل ايس ايس اي 99٪ سوڊيم سلفيٽ اينهائيڊروس صابڻ/گلاس/ڊٽرجنٽ ٺاهڻ لاءِ

سٺي سروس، اعليٰ معيار جي شين جي هڪ قسم، مقابلي واري قيمتن ۽ موثر ترسيل جي ڪري، اسان پنهنجي گراهڪن ۾ سٺي شهرت حاصل ڪريون ٿا. اسان هڪ متحرڪ ڪمپني آهيون جنهن وٽ صنعتي گريڊ ڪيميڪل ايس ايس اي 99٪ سوڊيم سلفيٽ اينهائيڊروس صابن/گلاس/ڊٽرجنٽ ٺاهڻ لاءِ وسيع مارڪيٽ آهي، اسان دنيا جي ڪمپنين سان مثبت ۽ فائديمند لاڳاپا ٺاهڻ جا منتظر آهيون. اسان توهان کي گرمجوشي سان ڀليڪار ڪريون ٿا ته اسان سان رابطو ڪريو ته جيئن اسان ان کي ڪيئن وجود ۾ آڻي سگهون ٿا ان تي بحث شروع ڪري سگهون.

سٺي سروس، اعليٰ معيار جي شين جي هڪ قسم، مقابلي واري قيمت ۽ موثر ترسيل جي ڪري، اسان پنهنجي گراهڪن ۾ سٺي شهرت حاصل ڪريون ٿا. اسان هڪ متحرڪ ڪمپني آهيون جنهن جي وسيع مارڪيٽ آهي، اڄ، اسان وٽ سڄي دنيا مان گراهڪ آهن، جن ۾ آمريڪا، روس، اسپين، اٽلي، سنگاپور، ملائيشيا، ٿائيلينڊ، پولينڊ، ايران ۽ عراق شامل آهن. اسان جي ڪمپني جو مشن بهترين قيمت سان اعليٰ معيار جو سامان فراهم ڪرڻ آهي. اسان توهان سان ڪاروبار ڪرڻ جي منتظر آهيون.

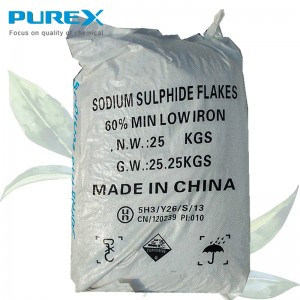

سوڊيم سلفائيڊ سامان جي سار سنڀال لاءِ مهارت جي ضرورت آهي. رد عمل واري ڪيٽل جي اسٽرنگ پيڊلز کي هر مهيني سنکنرن لاءِ معائنو ڪيو وڃي، ۽ 1 ملي ميٽر کان وڌيڪ ٿلهي وارن پيڊلز کي تبديل ڪيو وڃي. سوڊيم سلفائيڊ ويئر مزاحمتي لائنر پائپ لائن جي موڙ تي نصب ڪيا وڃن، ۽ اينڊو اسڪوپ استعمال ڪندي هر ٽن مهينن ۾ لباس جي جانچ ڪئي وڃي. والو سيلنگ گيسڪٽس پولي ٽيٽرافلووروٿيلين (PTFE) مان ٺهيل هجڻ گهرجن، ڇاڪاڻ ته عام رٻڙ گيسڪٽس ڇهن مهينن اندر خراب ٿي سگهن ٿا ۽ سوراخ ڪري سگهن ٿا.

سوڊيم سلفائيڊ سامان جي سار سنڀال لاءِ مهارت جي ضرورت آهي. رد عمل واري ڪيٽل جي اسٽرنگ پيڊلز کي هر مهيني سنکنرن لاءِ معائنو ڪيو وڃي، ۽ 1 ملي ميٽر کان وڌيڪ ٿلهي وارن پيڊلز کي تبديل ڪيو وڃي. سوڊيم سلفائيڊ ويئر مزاحمتي لائنر پائپ لائن جي موڙ تي نصب ڪيا وڃن، ۽ اينڊو اسڪوپ استعمال ڪندي هر ٽن مهينن ۾ لباس جي جانچ ڪئي وڃي. والو سيلنگ گيسڪٽس پولي ٽيٽرافلووروٿيلين (PTFE) مان ٺهيل هجڻ گهرجن، ڇاڪاڻ ته عام رٻڙ گيسڪٽس ڇهن مهينن اندر خراب ٿي سگهن ٿا ۽ سوراخ ڪري سگهن ٿا.